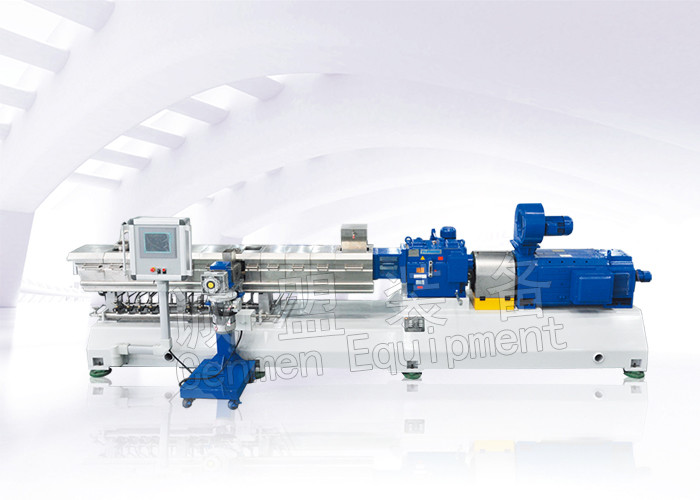

Co Rotating Twin Screw Compounding Extruder Machine High Torque TSH Series

Characteristics of twin screw extruder

Co-rotating modular design has the advantage of strong conveying, mature plastification, blending and compounding, interface refreshing, self cleaning, shearing and dispersing, venting and devolatilization, etc.

Characteristics of modular screws

The extruder is assembled according to the modular design theory, which can use the given screw bushes, kneaders, disks, shear rings and kneading elements to make versatile screw configurations to meet all kinds of material systems and critical process requirements.

Characteristics of New (One Step) Forming Production Line

Combines the polymer compounding pelletizing and product forming industry, adopts new equipment and technology to realize the integration of the two major process of compounding modification and extrusion forming process with continuity and automation control. Shorten and simplify the process dramatically, reduce plant occupancy and workers, cut down the energy consumption and production cost heavily, at the same time, reduce the heating experience and improve and enhance the comprehensive quality of products.

◆ Extend to the up stream raw material conveying and metering system, adopt the advanced continuous multi and gravimetric feeding to realize the seamless integration of the metering system and the compounding unit.

◆ Integration and interaction with other forming technology continuously. Including but not limited to all kinds of functional sheet, panel, pipe and film products and multi-layer co-extrusion, new type hollow composite structural sheet & board, glass fiber reinforced composite panel, super critical fluid foaming sheet & panel, on line spinning forming, etc.

◆ Be capable to extend to up stream polymerization process; and for some new materials, reaction extrusion and devolatization after polymerization, online modification and super critical foaming or other extrusion forming with large span and ultra-short peocess are possible; which can improve the technology dramatically.

◆ Integration of the polymer material, process, equipments and automation control technology to offer the customer with creative innovation of polymer process; we can offer tailored proposal for customer for one step process, new process and offer TUNE KEY project.

| 型号 |

公称直径D(mm) |

长径比

(L/D)

|

主电机功率

(kw)

|

螺杆转速

(rpm)

|

最大扭矩

(N.m/Shaft)

|

扭矩等级

(T/A3)

|

参考产量

(kg/h)

|

| TSH |

15 |

15 |

36-66 |

2.2 |

500 |

20 |

8.8 |

0.5-8 |

| TSH |

25 |

26 |

36-66 |

7.5-15 |

400-800 |

86 |

8.1 |

5-60 |

| TSB |

35 |

36 |

32-68 |

15-30 |

500-800 |

173 |

6.4 |

10-90 |

| TSH |

36 |

32-68 |

22-37 |

500-800 |

229 |

8.5 |

20-150 |

| TSS |

36 |

32-68 |

30-45 |

500-800 |

275 |

10.2 |

50-200 |

| TSB |

40 |

41 |

32-68 |

22-37 |

400-800 |

252 |

6.1 |

65-150 |

| TSH |

41 |

32-68 |

37-55 |

500-800 |

344 |

8.4 |

110-230 |

| TSS |

41 |

32-68 |

45-75 |

500-800 |

430 |

10.5 |

135-375 |

| TSB |

52 |

52 |

32-68 |

45-75 |

500-800 |

429 |

5.4 |

135-300 |

| TSH |

52 |

32-68 |

75-110 |

500-800 |

688 |

8.6 |

225-500 |

| TSS |

52 |

32-68 |

90-160 |

500-800 |

900 |

11.3 |

270-600 |

| TSB |

65 |

62 |

32-68 |

90-132 |

500-800 |

860 |

5.9 |

250-550 |

| TSH |

62 |

32-68 |

132-200 |

500-800 |

1222 |

8.7 |

400-800 |

| TSS |

62 |

32-68 |

160-250 |

500-800 |

1467 |

10.4 |

480-1000 |

| TSB |

75 |

72 |

32-68 |

132-200 |

500-800 |

1261 |

5.8 |

400-800 |

| TSH |

72 |

32-68 |

200-280 |

500-800 |

1910 |

8.8 |

600-1200 |

| TSS |

72 |

32-68 |

250-355 |

500-800 |

2407 |

11.1 |

750-1600 |

| TSB |

85 |

82 |

32-68 |

200-220 |

500-600 |

1834 |

5.9 |

600-1000 |

| TSH |

82 |

32-68 |

280-355 |

500-600 |

2674 |

8.6 |

800-1600 |

| TSS |

82 |

32-68 |

355-400 |

500-600 |

3255 |

10.5 |

1000-1800 |

| TSB |

95 |

92 |

32-68 |

315-355 |

500-600 |

2887 |

6.1 |

840-1600 |

| TSH |

92 |

32-68 |

450-550 |

500-600 |

4202 |

8.9 |

1350-2750 |

| TSS |

92 |

32-68 |

550-650 |

500-600 |

5043 |

10.6 |

1650-3250 |

| TSB |

115 |

116.5 |

32-68 |

400-560 |

400-550 |

4600 |

5.3 |

900-2800 |

| TSH |

116.5 |

32-68 |

630-800 |

400-550 |

7200 |

8.2 |

1600-3500 |

| TSB |

125 |

126 |

32-68 |

560-710 |

400-500 |

6400 |

5.7 |

1450-3100 |

| TSH |

126 |

32-68 |

800-900 |

400-500 |

9170 |

8.2 |

2000-4000 |

| TSB |

135 |

133.5 |

32-68 |

630-800 |

400-500 |

7400 |

5.6 |

1900-3500 |

| TSH |

133.5 |

32-68 |

1000-1250 |

400-500 |

11460 |

8.6 |

3000-5600 |

| TSB |

150 |

150 |

32-68 |

710-1120 |

300-500 |

10850 |

5.6 |

2100-5000 |

| TSH |

150 |

32-68 |

1000-1800 |

300-500 |

16500 |

8.5 |

3000-8000 |