Polymer Waterproof Membrane Compounding Extrusion Calendering Forming Production Line

Introduction of Polymer Waterproof Membrane:

Waterproof membrane is one of the most important constructional waterproof material, and in its practical application, bitumen is most commonly being used and occupying 65-70% market portion. In recent years, polymer material waterproof membrane application is on the rise, especially for a new type of polymer material called TPO.

The three major polymer material for waterproof membrane are: Ethylene propylene diene rubber (EPDM), polyvinyl chloride (PVC), polyolefin (TPO, EVA, HDPE), and each possesses own characteristic.

| |

EPDM |

PVC |

TPO, EVA, HDPE |

| Tensile property |

Tensile strength≥7mpa

Elongation≥400%

|

Tensile strength≥12mpa

Elongation≥250%

|

Tensile strength≥12mpa

Elongation≥500%

|

| Temperature resistance |

-40℃ |

-25℃ |

-40℃ |

| Aging Resistance |

Tension retention≥80%

Elongation retention≥70%

|

Tension retention≥80%

Elongation retention≥70%

|

Tension retention≥90%

Elongation retention≥90%

|

| Weatherability |

No harmful substances volatilization, migration, surface dust. |

Containing a large amount of plasticizer surface migration, small molecule additives such as stabilizers are easy to precipitate. |

Clean materials - no dust adsorption, no volatilization and migration of harmful substances, building roof bright and clean |

| Recyclability |

Recyclable |

Degradation is serious and should not be recycled |

Recyclable |

| Environmental performance |

Chlorine-free elements, no harmful substances volatilization during heating, no harm to construction personnel and the environment |

Chlorine-containing elements volatilize hydrogen chloride after heating, causing harm to people and the environment |

Chlorine-free elements, no harmful substances volatilization during heating, no harm to construction personnel and the environment |

| Appearance |

Black surface, absorb sunlight, increase indoor temperature |

Light-colored surface, reflecting sunlight, reduce energy consumption in the house.

|

Light-colored surface, reflecting sunlight, reducing roof energy consumption. |

| Construction method |

It can only be mechanically fixed and glued with low reliability. |

It can be mechanically fixed, glued and hot-air welded with high reliability. |

It can be mechanically fixed, glued and hot-air welded with high reliability. |

Polymer waterproof membrane product Illustration:

1. Homogenized membrane;

2. Membrane with fabric backing;

3. Intermediate reinforcement membrane;

4. Membrane with both Intermediate reinforcement and fabric backing.

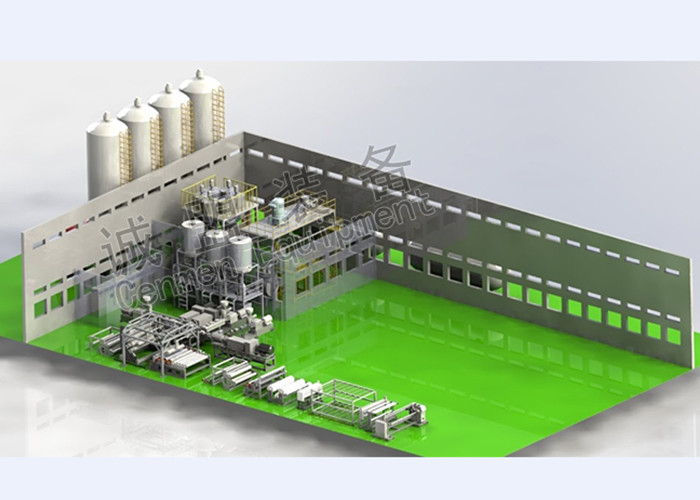

Polymer waterproof membrane forming technic illustration:

- Whole production line using one-step processing method.

Using one-step processing method can significantly increase the final product performance and by simplifying the pelletizing process, labor force, packing, transition and etc. costs will get lower. Also one-step processing method is fully automatized, in-time correcting any glitch may occurred during producing.

- Equipment characteristics:

Automatic raw material feeding system: Automation Control, only additives need to quantitatively weighting manually. After mixing, all material automatically transported to the feeding silo on the weight -loss scale. The control accuracy of weighing sensor is 0.5%. Siemens PLC chain control is used in the control system.

Loss in weight feeder: Effective guarantee for the accuracy of material formulation. Traditional feeding methods, such as high mixing, volume feeding and so on, will result in material stratification and product instability, while weightlessness scale can ensure that the accuracy of the formula ratio reaches three thousandths, which is an important means to ensure the stability of product performance.

Twin screw extruder: By mixing, dispersing and extruding raw materials fed in proportion, good dispersion, distribution, homogenization, average, plasticization and mixing effects can be achieved. The screw assembly can be adjusted according to the formula of the material. The movable bed is used to replace and clean the screw, which further improves the properties of the material such as stretching and elongation. The high-efficiency vacuum exhaust device is also equipped to effectively remove the low molecular weight and moisture in the material, thus ensuring that no crystal point will be produced in the process of the product. And bubbles. Our company is the domestic twin screw manufacturing enterprises with the most standard scale, the mixing effect of twin screw is the first means to protect products.

Conical twin screw melt pump: It can establish the pressure of material, ensure the stable pressure of material, and equalize the pressure of extrusion. And effective control of material temperature.

Sheet forming machine: equipped with four-roller forming machine, the upper roller diameter is 500 mm, the lower roller diameter is 800 mm, which effectively ensures the effective forming and cooling of elastomer, EVA and other sheets. Large roll diameter is convenient for space operation, and equipped with two cooling rolls for cooling. Servo drive system and permanent magnet synchronous motor are used to control the motor, which has high performance of fast response, wide speed range and accurate positioning. The six-roll cooling system in the rear track can ensure the rapid and effective shaping and cooling of products. This set of configuration and the mechanism of rollers are designed with reference to the German "Klaus Maffe" waterproof membrane equipment.