| Place of Origin: | China |

| Brand Name: | Cenmen |

| Certification: | CE, ISO9001 |

| Model Number: | TSH |

| Minimum Order Quantity: | 1 unit |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 20GP, 40HC,40HQ |

| Delivery Time: | 60 work days |

| Supply Ability: | 300 units per year |

| Material: | SBS / SEBS Material | Application: | Granules |

|---|---|---|---|

| Product Name: | Thermoplastic Elastomer Material | Screw Design: | Double Screw |

| Cutting Mode: | Water Ring Cutting | ||

| High Light: | sbs thermoplastic elastomer,biodegradable thermoplastic elastomer |

||

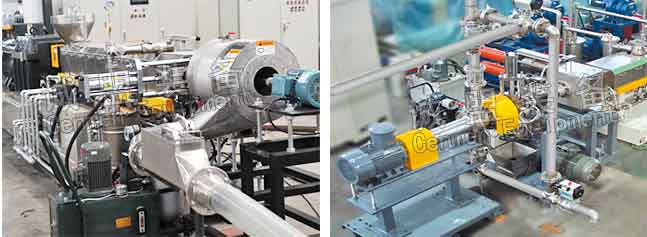

TPE/TPV Elastomer pelletizing line

Elastomer compounding modifying ——SBS/SEBS Compounding modifying

Application

The thermoplastic Elastomer is abbreviated as TPE. The most common TPE material is SBS/SEBS modified material. TPE is a rubber with high elasticity , It also has the characteristics of injection molding, it has a wide range of hardness, superior processing performance, no need for vulcanization, and can be recycled to reduce costs. Mainly used in various types of seals, automotive interiors, rubberized materials, various pipe fittings, wire and cable etc.

SBS or SEBS compounding modification adjusts the ratio between SBS/SEBS, PP, filler and filling oil according to different hardness requirements. PP provides rigidity, increase SBS/SEBS and filling oil to improve flexibility.

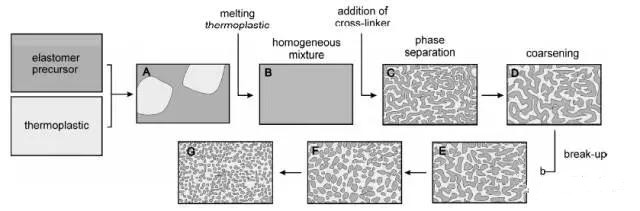

Elastomer compounding modifying - TPV Dynamic Vulcanization process description

Application

Thermoplastic Vulcanizate is abbreviated as TPV, It is called dynamic vulcanization process in the industry. The current composition is PP, EPDM, filler, filling oil, crosslinking agent and processing additives. The so-called dynamic vulcanization means that the vulcanization (crosslinking) of the rubber and the melt dispersion are simultaneously performed, and the vulcanized rubber phase uniformly disperses the continuous phase of the resin to form rubber particles having a particle size of 1 to 2 μm under severe shearing action. TPV products are mainly used in various types of seals, soles, various pipe fittings, wire and cable, etc.

Equipment Characteristics:

1. Adopt high speed and high torque twin screw extruder. The high torque can withstand higher loads and adapt to the high melt strength of the vulcanized rubber; the high screw speed provides a higher shear rate, disperses the vulcanized rubber into small-sized rubber particles and uniformly disperses in the resin.

2. Large L/D screw barrel and multi-way dosing feeding. Large L/D=48:1~52:1 provides longer residence time, which is beneficial to complete complex mixing process of melt homogenization, vulcanization and dispersion. At the same time, it is equipped with multiple sets of dosing feeders to feed the resin, rubber, filler, filling oil and the crosslinking agent into the barrel step by step.

3. High precision screw and barrel design. The screw and barrel have small gap and high dimensional accuracy, and the screw structure is optimized to effectively complete the homogenization process of resin melting and filling oil, and complete the dynamic vulcanization process by shearing and dispersing elements.

4. The pelletizing method is selected according to the melt characteristics. Different raw materials and ratios in the formulation have large differences in melt characteristics. The higher hardness products can select water cooling strand pelletizer, and the low-viscosity and easy-adhesive products can adopt under water pelletizer.

The above description is a one-step dynamic vulcanization process, which is suitable for production conditions with stable formulation ratios. In actual production, due to different product performance requirements, the proportion of each component in the formulation varies greatly, and the proportion and degree of vulcanized rubber are also quite different. The two-steps dynamic vulcanization process will have stronger applicability. That is, two sets of twin-screw extruder production lines:

1. The first twin-screw extruder is to uniformly mix PP, EPDM, filler and a small amount of filling oil and then pelletizing.

2. The second twin-screw extruder is for compounding the polymer, most of the filling oil and crosslinking agent to complete the crosslinking of the EPDM and uniformly disperse it.