| Place of Origin: | China |

| Brand Name: | Cenmen |

| Certification: | CE, ISO9001 |

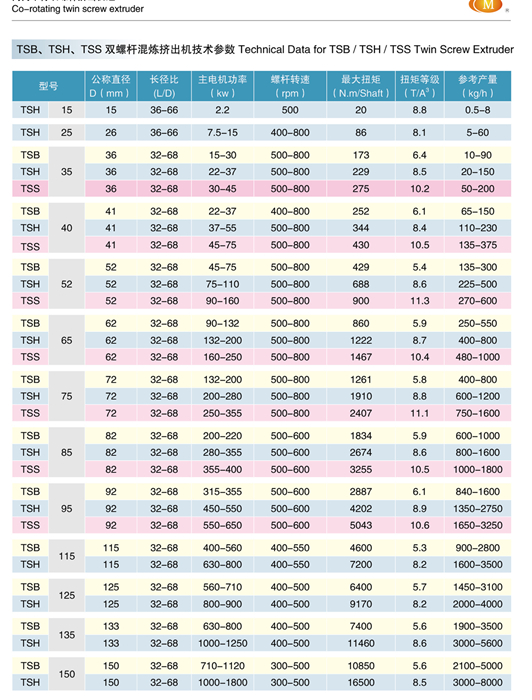

| Model Number: | TSH |

| Minimum Order Quantity: | 1 unit |

|---|---|

| Price: | Negotiation |

| Packaging Details: | 20GP, 40HC,40HQ |

| Delivery Time: | 60 work days |

| Supply Ability: | 300 units per year |

| VOLTAGE: | 380/400/415V/50HZ/3PH(CUSTOMIZED) | Processing Material: | PP/PA+GF Reinforced Modification |

|---|---|---|---|

| Pelletizzing Mode: | Water Cooling Strand Cutting | ||

| High Light: | plastic compounding equipment,conical twin screw extruder |

||

Reinforcement Modification-addition of Glass Fiber to Polymer to increase rigidity (strength and Modulus).

Common polymer resins: PA, PP, common fibers: glass fibers, carbon fibers.

The dispersion and length of glass fiber in resin: the distribution of glass fiber in the resin is uniform, the longer the retention length and the better the effect

Glass fiber content: common glass fiber content 30%~50%. The higher the glass fiber content, the better the rigidity, but the surface finish and fluidity will decrease.

Surface treatment of glass fiber: surface treatment can increase the bonding ability between glass fiber and resin interface, thereby improving the mechanical properties.

Selection of resin grade: make higher glass fiber content, or larger volume of products, should choose a higher value of melting finger. High flow numerical value contributes to the dispersion of glass fibers and the forming of bulk products.

Feeding mode--Adopting the form of multichannel feeding.

Plastic particles, auxiliaries and powders were fed separately by weight-loss scales, and high content fillers were fed with two sets of lateral feeding. High ratio accuracy, avoid delamination and bridge building.

Glass fiber is usually added in the middle and rear part of the cylinder, short cut glass fiber is added by feeding machine, and long glass fiber is added directly by opening.

Barrel L/D——L/D=36:1~44:1

Under normal conditions, L/D=40:1 can meet the needs of mixing. Side feeding, exhaust port and vacuum port will increase L/D of the barrel.

Pelletizing mode--Melt characteristics, process requirements.

According to the viscosity, strength, hardness and other technological factors of the melt, select the specific granulation mode, the most common is the water-cooled pull-type grain cutting; low hardness-water ring; melt easy adhesion-underwater pelletizing.

Process flow chart(steel frame platform+loss-in-weight feeder+liquid injection+pelletizing production line)