Thermoplastic Elastomer Modification—SBS/SEBS Compounding

The thermoplastic elastomer has the characteristics of high elasticity, high resilience and injection processing, and has the characteristics of wide hardness, soft touch, weather resistance, fatigue resistance and temperature resistance, superior processing performance, no need of vulcanization, and can be recycled and used for reducing cost.

The most common TPE is modified by SBS or SEBS blending. According to different hardness requirements, the ratio of SBS/SEBS,PP, filling oil is adjusted.PP provides rigidity. The increase of SBS/SEBS and filling oil can improve flexibility.

| Item |

Proportion |

Description |

| Styrene elastomer |

50~60 |

SBS,SEBS and other multicomponent copolymer elastomers. |

| Sulan |

30~60 |

The most common material is PP providing rigidity, and adjusting the softness of the product. |

| Filling |

0~20 |

Increase rigidity and reduce thermal shrinkage of products. |

| Technical white oil |

0~20 |

Plasticizer, adjust the softness of the product. |

| Additive |

0.5~3 |

Anti oxygen, etc. |

| Masterbatch or toner |

1~2 |

Increase whiteness or change other colors according to product requirements |

Feeding mode--Common feed for high mixer after premixing

SBS/SEBS,PP, filling oil, auxiliaries, etc are mixed uniformly in the high mixer, so that the filling oil is completely absorbed by SBS/SEBS.

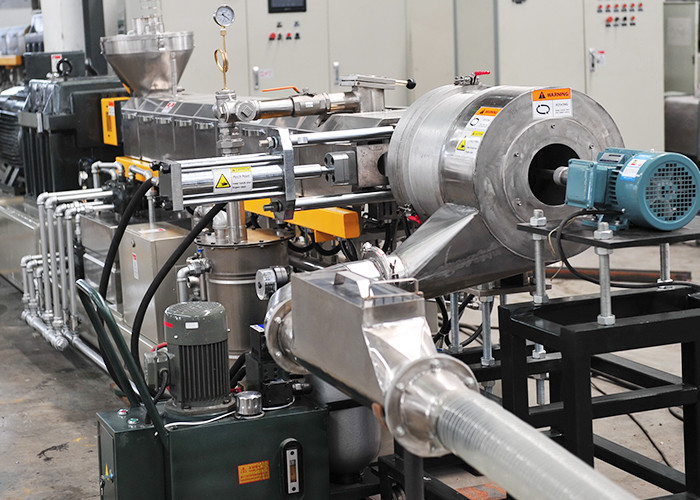

Feed into twin screw extruder through feeder

Barrel L/D——L/D=44:1~52:1

Under normal conditions, L/D=48:1 can meet the needs of mixing. Side feeding, exhaust port and vacuum port will increase L/D of the barrel.

Pelletizing mode--Melt characteristics, process requirements.

According to the viscosity, strength, hardness and other technological factors of the melt, select the specific granulation mode, the most common is the water-cooled pull-type grain cutting; low hardness-water ring; melt easy adhesion-underwater pelletizing.

Process flow chart(steel frame platform+loss-in-weight feeder+liquid injection+pelletizing production line)