3-layers Stone Paper Packing Board Illustration

Material formula: Sheet size: Applications:

PP/PE:15-25% Width:1000-1500mm Various harden packing box carboard series

Caco3:70-80% Thickness:2-4mm

Auxiliary agents:3-8%

Using high CaCO3 content (75-85%) and regular polymer as raw material, compounding and 3 layers co-extrusion by screw extruder, recombined forming the high filling composite packing board. Because of its high strength, non-deformability and good protective performance, it can provide many high-quality characteristics, such as quality preservation, water-proof and moisture-proof, mildew-proof and moth-proof, reusable and cost-reducing. It can be widely used in various kinds of container packaging for logistics transportation, providing the best green packaging scheme with high performance, high cost and high protection.

This environmental protective packing board is capable of multiple recycling, the wasted packing board can be recycled by fracturing, melting, re-pelletizing and forming again through extrusion system.

This packing board is degradable eco-friendly material at the same time, during a period time of weathering, the filler content from the packing board will completely come off and since the filler content is as much high as over 75%, the remaining cellular structure connective polymer material will become pollution-free, which means the whole packing board is naturally degradable.

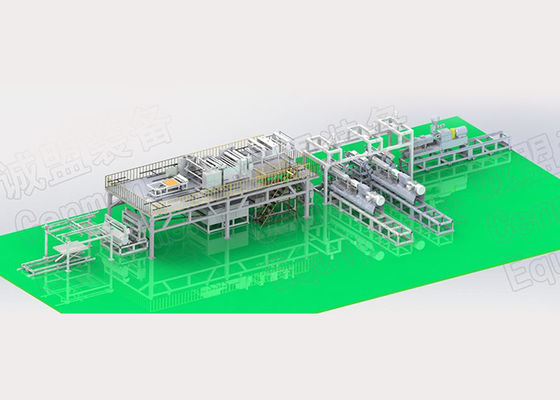

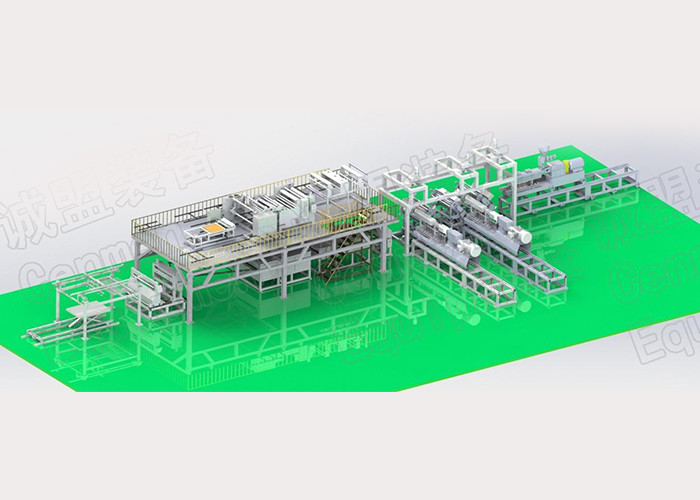

Environmental Protective High filling Composite Packing Board Production Line Equipment Illustration:

The whole production line includes: Compounding extrusion system, T-die mould system, 3-layers recombined forming system, final product tempering heat treatment and cooling shaping system, fracking fixed length shearing and automatic stacking system. The main technic for this 3-layers recombining is extrusion calendering forming for the middle core layer first, and this core layer has a conical or polygonal concave and convex surfaces structure, then thermo pressing with top and bot tom layers in step, which forming a 3-layers composite material packing board.