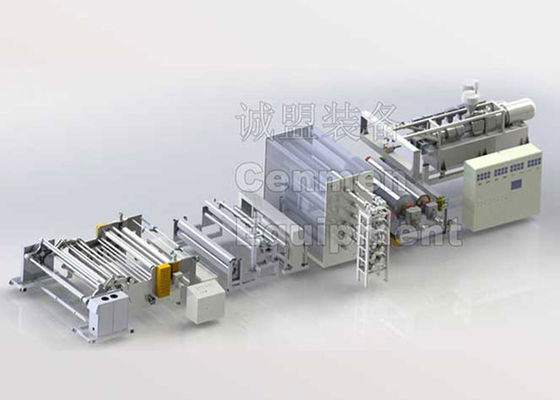

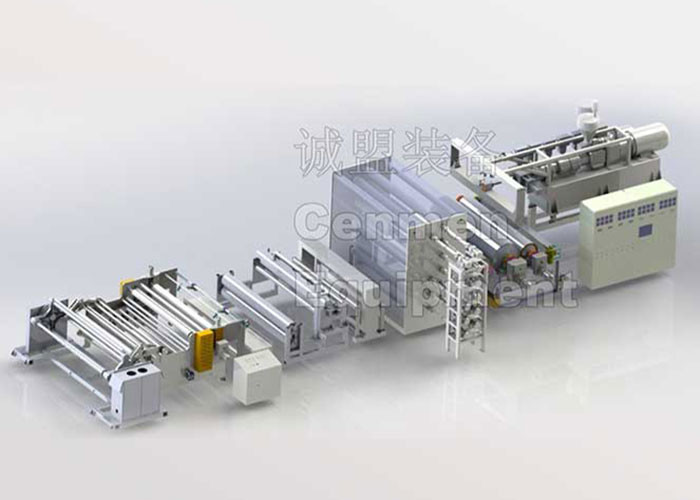

PP, PE Air Permeable Film Compounding Extrusion Casting Stretch Forming Production Line

Introduction:

PP, PE Air permeable film is a new type of material in the world, with the characteristics of air permeability and no leakage, is widely used in many areas of life products: such as sanitary napkins, diapers bottom, medical surgical clothing and one of the fabrics of breathing paper in the construction industry, as well as other packaging products. This air permeable film contains high percentage (50-60%) ultra-fine density inorganic filler, through calendering, stretch treatment, Forming numerous micropores and uniform distribution. The micropores diameter of 0.1-10 um and they are permeate only air but not liquids.

Normal air permeable film are using two steps processing method, the first step is using kneader + single screw extruder to form PE polymer resin, inorganic filler and additives for compounding and pelletizing. Second step using single screw extruder for extrusion casting and stretch forming technic. This two steps processing method has high power consumption but low efficiency, since it does not possess enough compounding effect for the inorganic filler. As a result, the distribution of micropore is not uniform and the pore size fluctuates greatly, which makes it impossible to produce high-end and middle-end products.

Equipment Introduction:

CENMEN One step processing method production line includes: raw material supplying system, twin screw compounding extruder, screw pump, extrusion forming system, stretch shaping system, cooling and winding system. Consecutively processing raw material proportional feeding, compounding for material evenly dispersion, extrusion casting, stretch shaping and winding. The advantages of this method is listed below:

-

The whole production line is consecutively producing, high efficiency. Complete the whole production process from raw materials to air permeable film in one time.

-

The raw material supplying system complete the processes of storage, transition and accurately feeding. High automation and the whole production process is dust free.

-

High torque gearbox is equipped for the twin screw extruder for high production efficiency. Low gap distance and high-precision for the barrels and screws, which provides an even dispersion and distribution for compounding the PE polymer resin with the inorganic filler. Lower aperture and evenly distributed micropores for the final film product.

-

The extrusion forming system is equipped with high-precision mould die and pressing roller, which provides stable casting forming effect and uniform thickness final product.

-

Stretch shaping system is compose by heating device, stretch device and cooling device, stable operation and uniform drawing ratio.